Granulation helps ensure the drug ingredients are evenly distributed in the final product, improving dosage accuracy and product quality consistency.

High-Performance Pharmaceutical Granulation Machines

Pharmaceutical Granulation Solution

Canaan Technology specializes in pharmaceutical granulation equipment and technologies that transform fine powders into high-quality granules—ideal for the production of tablets, capsules, and other solid dosage forms. Our granulation process meets the highest standards of efficiency, consistency, and regulatory compliance.

What is Granulation in Pharmaceutical Industry?

Granulation in the pharmaceutical industry is the process of converting fine powders into cohesive granules, improving flowability, compressibility, and content uniformity. This step is crucial for consistent tablet quality and dosage accuracy.

- Improve Flowability

The granulation process makes powder particles more uniform, improving their flow through production equipment and reducing clogging and inconsistencies.

- Enhance Compressibility

Granulation gives powder particles better compression properties, allowing the formation of tablets with moderate strength and smooth surfaces.

- Ensure Uniformity

Types of Granulation in Pharmaceutical Industry

- Wet Granulation

Producing dense, controlled-release particles with high drug solubility. A binder solution is added to form a moist mass, followed by drying and sizing.

Features:

- Less material and energy loss

- WIP/CIP

- Closed system

- Comply 21CFR Part 11 requirement

- Comply GMP/FDA requirement, CE certified

Capacity:

- From 1L (Lab) to 1500L (Production)

- Scale up

- Changeable Bowl

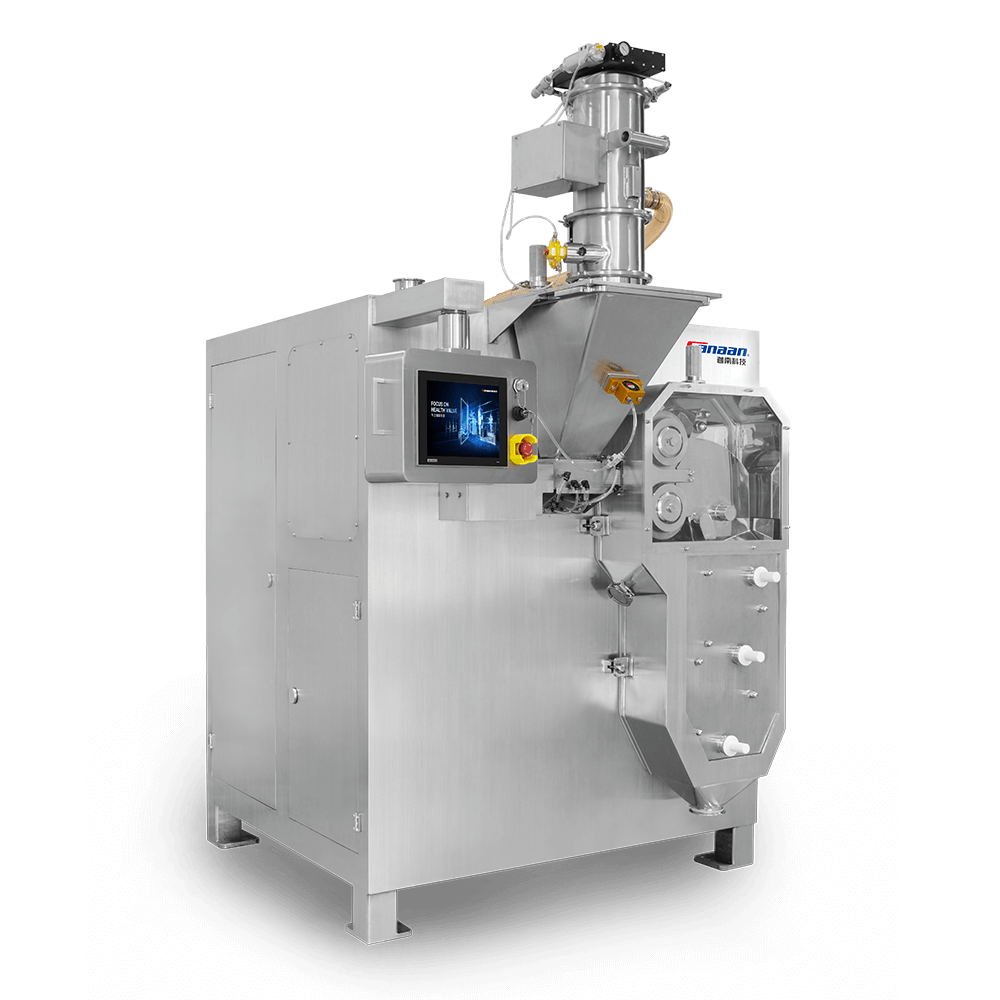

- Dry Granulation

Dry granulation is ideal for processing heat-sensitive or moisture-absorbing materials.

Features:

- Less material and energy loss

- WIP/CIP

- Closed system, dust free

- Comply 21CFR Part 11 requirement

- Comply GMP/FDA requirement, CE certified

Capacity:

- From 0.1kg/h-700kg/h

- Scale up

- Dry Granulation

Dry granulation is ideal for processing heat-sensitive or moisture-absorbing materials.

Features:

- Less material and energy loss

- WIP/CIP

- Closed system, dust free

- Comply 21CFR Part 11 requirement

- Comply GMP/FDA requirement, CE certified

Capacity:

- From 0.1kg/h-700kg/h

- Scale up

- One-step Granulation (Boiling Granulation)

Integrated drying, granulation, and coating, it reduces labor works and control cross-contamination.

Features:

- Ex-proof (ATEX certified), more safety

- WIP/CIP

- Wall-mounted design, space saving

- Comply 21CFR Part 11 requirement

- Comply GMP/FDA requirement, CE certified

Capacity:

-

From 0.5kg/batch-500kg/batch

(top spray) - Scale up

Canaan Wet Granulation Line for Pharmaceutical Industry

Canaan X Series Wet Granulation Line is a high-containment, automated pharmaceutical production system. It includes multiple interconnected processing units for wet granulation, typically used in the production of solid oral dosage forms like tablets and capsules.

The Granulation Line is integrated with:

- High Shear Mixer (HSM) – for wet granulation

- Fluid-Bed Processor – for drying and possible coating

- Dry Milling Machine – for milling

- Coater – for coating

- Operation Interface – for process automation and control

Features:

- High efficiency

- Ex-proof

- Clean-in-place (CIP) or wash-in-place (WIP)

- High safety and containment (up to OEB5)

- Comply 21CFR Part 11 requirement

- Comply GMP/FDA requirement, CE certified

Contact Canaan

Request a Tailored Pharmaceutical Granulation Solution for Your Project

Benefits you can get from Canaan:

Custom granulation machine for your pharmaceutical granulation project

Advanced granulation solutions

Full-process granulation technology consulting

Fully meets GMP, FDA, CE standards

Canaan - Your Trusted Pharmaceutical Granulation Machine Manufacturer

Canaan brings over 20 years of experience in delivering turnkey solutions for pharmaceutical granulation systems. From equipment selection to system integration and regulatory compliance, we provide complete, worry-free granulation solutions tailored to your production needs.

Founded in 2000 and headquartered in Wenzhou, China, Zhejiang Canaan Technology Limited is a global leader in pharmaceutical equipment manufacturing.

With over 1,700 customers across Germany, Italy, Japan, Korea, and beyond, we deliver advanced, high-performance solutions for pharmaceutical solid dosage production.

Our granulation systems are at the core of fully integrated OSD (Oral Solid Dosage) lines—engineered for efficiency, uniformity, and full regulatory compliance.

We proudly support global pharma leaders like Sanofi, GSK, Pfizer, MSD, Merk, Abbott, Bayer, Bosch etc. with reliable, innovative solutions.

Why Choose Canaan Technology

Canaan Your Trusted Partner:

- Over 20 years of industry experience

- Global clients including Sanofi, GSK, Pfizer, Abbott, etc.

- CE/ISO-certified and GMP/FDA-compliant machines

- Complete granulation lines and turnkey solutions

Solutions Include:

- Concept Design

- After-sales and Maintenance

- On site Commissioning

- Compliance Validation

- Engineering Project Management

Get Your Pharmaceutical Granulation Solution Right Now!

Meet Us at Industry Trade Shows

As a regular participant in leading global pharmaceutical and processing exhibitions, we warmly invite our partners and clients to visit us. We will be exhibiting at CPHI China (June 24–26, 2025, Shanghai, China) and CPHI Frankfurt (28-30 October, 2025, Frankfurt, Germany).

At these events, we will spotlight our high-performance wet granulation machines, designed to deliver exceptional efficiency, uniformity, and regulatory compliance in solid dosage production. Come explore our latest innovations and discuss tailored solutions for your pharmaceutical manufacturing needs.

Frequently Asked Questions

Table of Contents

What’s the Difference Between Wet and Dry Granulation?

| Aspect | Wet Granulation | Dry Granulation |

| Binder Use | Requires a liquid binder | No binder or liquid needed |

| Moisture Sensitivity | Not ideal for moisture-sensitive materials | Ideal for moisture- and heat-sensitive materials |

| Granule Strength | Produces dense, strong granules | Strength varies with compaction |

| Dust Generation | Minimal due to moisture | Higher dust during processing |

| Processing Time | Longer, includes drying step | Faster, no drying needed |

| Applications | Tablets, capsules, sprinkle granules | Friable powders, moisture/heat-sensitive formulations |

How Does the Granulation Process Work?

Mixing: Active ingredients and excipients are combined.

Granulation: The mixture is agglomerated via wet or dry methods.

Drying: (Only in wet granulation) The granules are dried to the desired moisture level.

Sizing: Granules are screened to ensure uniform particle size.

Our granulation process in pharmaceutical industry meets the strictest global pharma granulation guidelines.

Why is Granulation Important in Pharma?

Granulation plays a key role in pharmaceutical manufacturing, as it improves tablet granulation, ensures content uniformity, and enhances compressibility and flowability in solid dosage forms like tablets and capsules. It’s essential for ensuring consistent drug release and quality control.

+86-577-67378828

+86-577-67378828 canaan@chinacanaan.com

canaan@chinacanaan.com