Premium Granulation Solutions

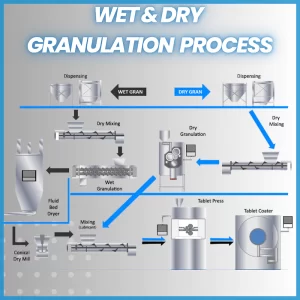

As a leading manufacturer of pharmaceutical granulation equipment, Canaan provides both Wet and Dry Granulation Machines tailored to your production needs. Let our expertise guide you in selecting the perfect solution for your process.

Discover Canaan's 4 Granulation Solutions

Canaan offers you two granulation methods: dry granulation and wet granulation, with 8 models of production machines.

Why Choose Wet Granulation for Your Manufacturing Needs?

Pros

Masks Tabulation Deficiencies Improved Compressibility Facilitates Tablet Coating Minimizes Dust Generation

Cons

Requires Specialized Equipment Higher Cost Energy-Intensive Not for Moisture-Sensitive Materials

Applications

Tablet and Capsule Manufacturing Nutritional Supplement Food Additives Powdered Cosmetics Fertilizer Production

Types

High Shear Mixer Fluid Bed Granulator

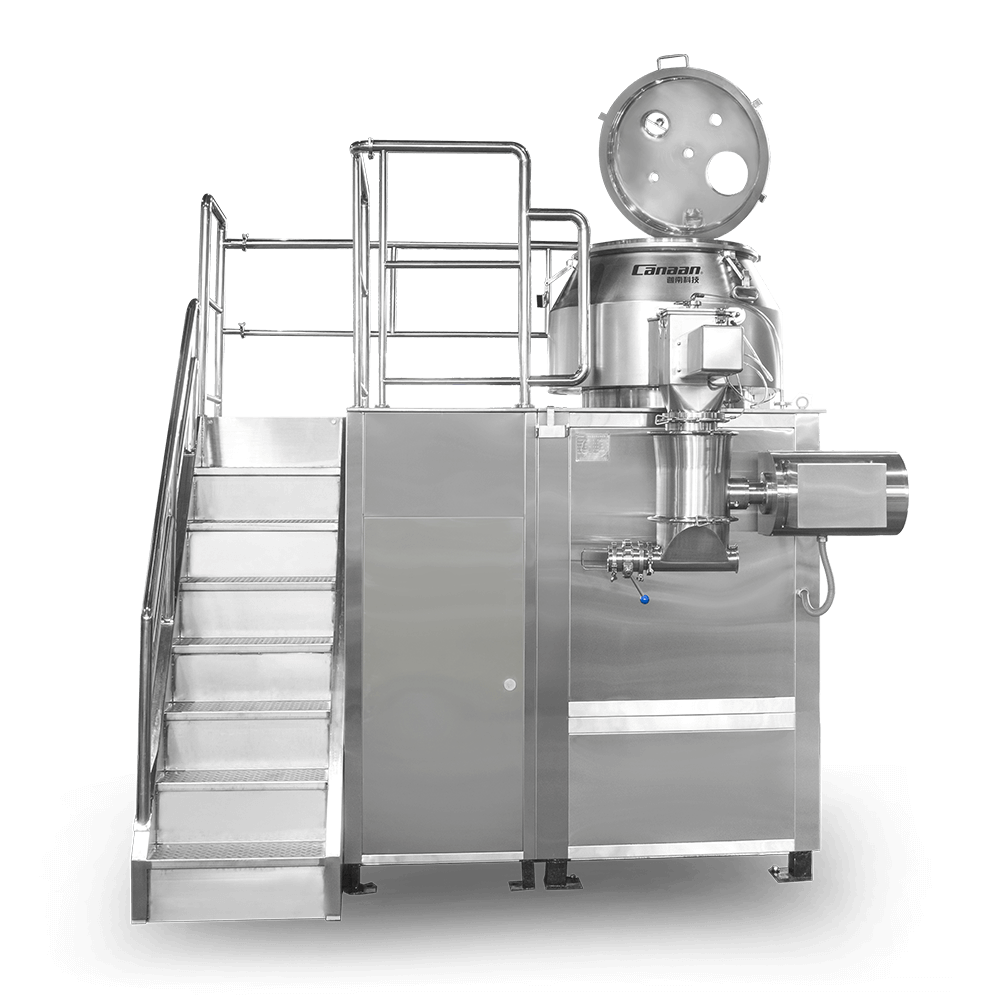

LHS Series High Shear Mixer

Working Principle:

- This High Shear Mixing Equipment completes mixing, binder charging, and granulating in one process.

- Impeller ensures uniform material movement in axial, radial, and tangential directions.

- Mixed powder combined with binders or wetting agents forms soft materials, cut into particles by the chopper.

- Wet granulation enhances surface, shape, wear resistance, and compressibility of granules.

FZ Serie Fluid-Bed Granulator

Working Principle:

- Material powder is placed into a container

- Air is used to suspend the powder, making it fluidized

- The binder is atomized and sprayed through a spray gun

- The binder agglomerates with the powder, forming particles

Optimize Your Production with Our High-Quality Wet Granulation Solutions

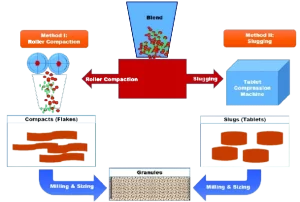

Wet Granulation VS Dry Granulation: What's the Difference?

5 Differences Between Wet and Dry Granulation You Need to Know!

Why Choose Dry Granulation for Your Manufacturing Needs?

Pros

Easier compressibility Adjustable process parameters Scalable Space-efficient Cost-effective

Cons

Higher percentage of fines Limited material suitability Requires specialized equipment Friable tablets Dust generation

Applications

Tablet and Capsule Manufacturing Battery Manufacturing Dietary Supplements Food Powders

Types

Roller Compactor Mill

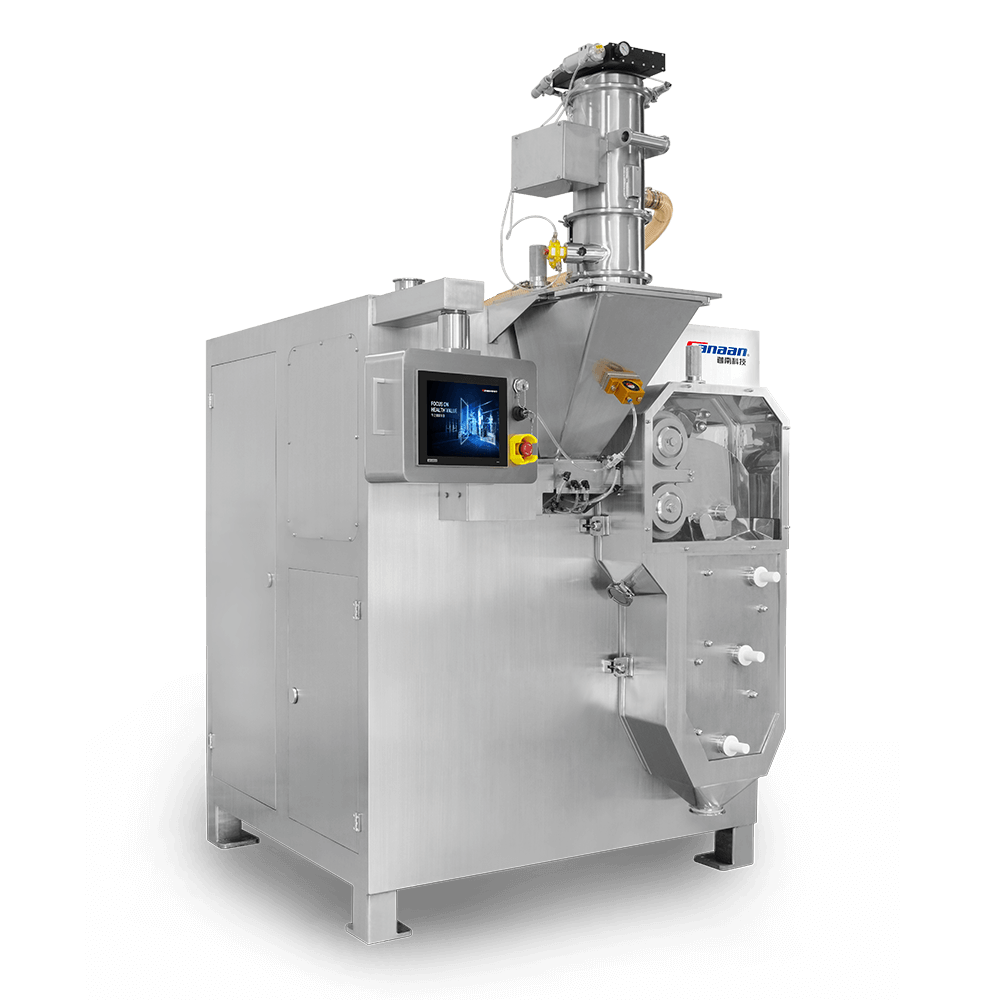

Roller Compactor Series

Our Roller Compactor Series is designed for efficient and reliable dry granulation across pharmaceutical, food, and chemical industries. From the precision of servo-driven models like the LGC and LGS Series to the robust performance of the LGP and LGX Series, each machine ensures consistent granule quality, easy operation, and durable performance, meeting the demands of diverse production needs.

Mill

Our Milling Solutions for dry granulation include the ZLT Series Lifting Mill and ZL Series Vacuum Mill, designed for efficient particle size reduction and material handling.

Optimize Your Production with Our High-Quality Dry Granulation Solutions

Why Choose Canaan's Granulation Solutions?

Why Trust Us?

Found in 2000, Zhejiang Canaan Technology Limited is one of the top pharmaceutical equipment manufacturers in China, we have totally 8 factories in China.

Our products cover from dispensing, granulation, blending, tablet compression, capsule filling, coating, packaging, water system to extraction solution and so on, by which we can provide complete line and turn key solution to customers.

Our products are widely used in food, chemical, pharma industries.

Meet Us at Industry Trade Shows

Canaan Technology participated in several major international exhibitions, including Pharmtech & Ingredients 2024 in Moscow, CPHI Worldwide 2024 in Milan, and Allpack Indonesia 2024 in Jakarta. These events allowed us to showcase our innovations and connect with industry leaders worldwide.

Download Our Full Catalogue Today

If you're interested in learning more about our granulation machines and would like to receive our full catalogue, please provide your name and email address below.

Complete our quote request form or email us at canaan@chinacanaan.com to receive a customized quote from our product specialists.

Contact Us

ask us

anything on Granulation

What is granulation in pharmaceutical ?

Granulation in the pharmaceutical industry refers to the process of agglomerating fine powders into larger, more uniform particles (granules). This process is crucial for improving the flowability, compressibility, and consistency of the material used in tablet and capsule manufacturing.

what are the advantages of dry granulation over wet granulation?

Dry granulation offers several advantages over wet granulation, particularly in terms of processing, cost-effectiveness, and material suitability.

What is the difference between high shear mixer granulator and rapid mixer granulator?

The High Shear Mixer Granulator (HSMG) and the Rapid Mixer Granulator (RMG) are both commonly used in the pharmaceutical industry for granulation, but they have some key differences in terms of design, operational characteristics, and application.

+86-577-67378828

+86-577-67378828 canaan@chinacanaan.com

canaan@chinacanaan.com