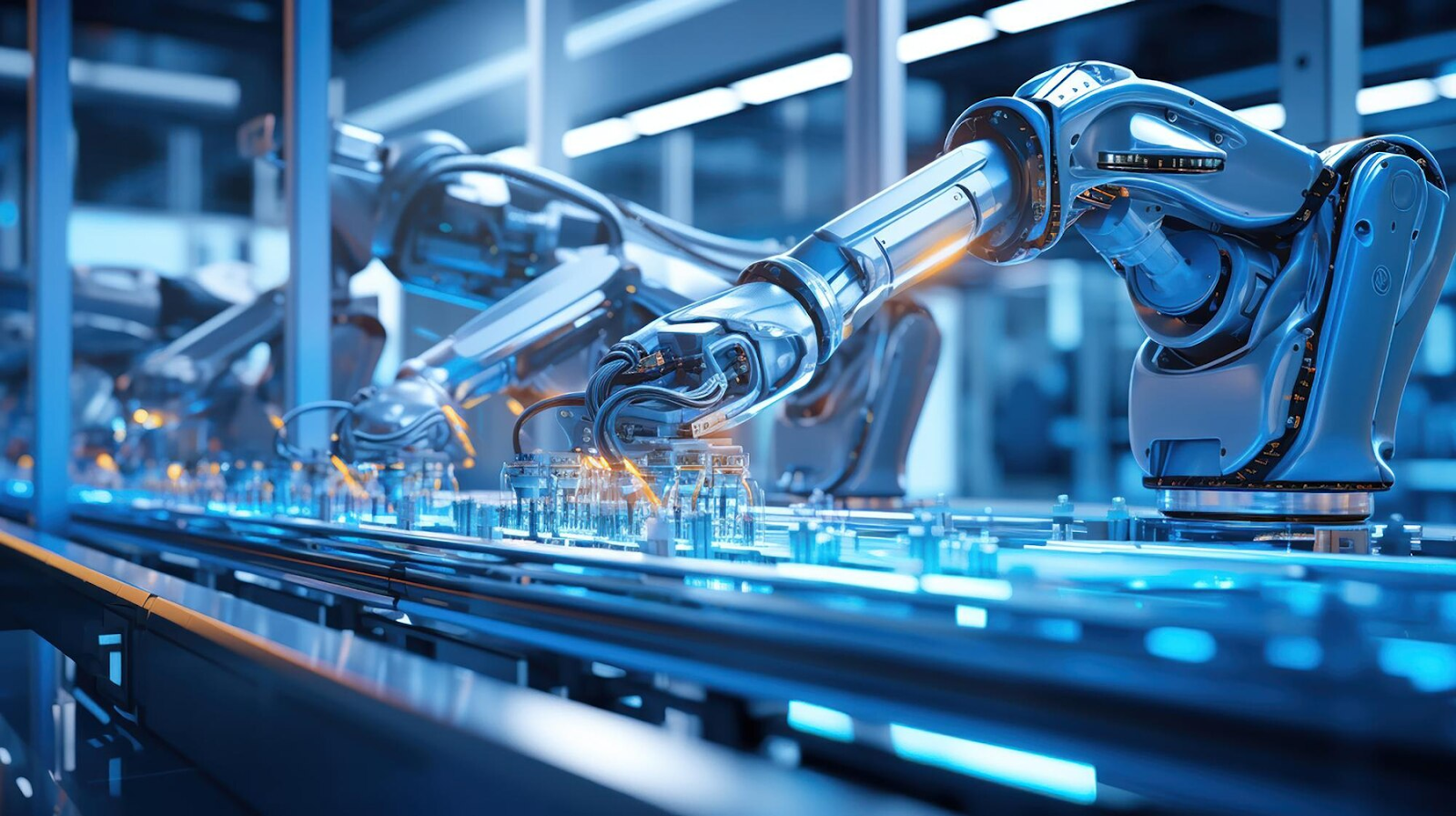

Nowadays, not investing in automation technologies is a matter of life and death for your industry. Several businesses are implementing these, such as automation in pharma industry, so why shouldn’t you?

Two of the most crucial concepts to understand about this technology, especially in pharmaceuticals, are the Supervisory Control and Data Acquisition or SCADA software, and the Programmable Logic Controllers or PLC computerized systems. SCADA monitors industrial processes, while PLC systems are for control.

Learn more about SCADA and PLC in this discussion by Canaan that will tackle the following:

– What is SCADA?

– How about PLC?

– The automation roles of SCADA and PLC

– The Canaan technology

The Supervisory Control and Data Acquisition software is used to present the state of your facility. With this software by your side, you can appropriately manage your industrial factory.

Developers of SCADA will visualize the factory and its processes, showing you its state in a simpler and more purposeful way.

Several industrial processes depend on the SCADA software. It can provide information in real-time, paving the way for efficient, reliable, and safe industrial processes and operations.

Through this software, huge amounts of data can be stored. You may also connect them to a wide range of sensors for remote process monitoring.

SCADA applications are beneficial where industrial processes have limited human control and interference. For instance, in the automation in pharma industry where human presence is limited in crucial processes, such as the packaging of the drug.

Several industries are invested in SCADA, whose market is projected to reach $26.6 billion by 2032.

Subsequently, Programmable Logic Controllers refer to computerized systems utilized for the control and automation of industrial processes, but particularly those involving your equipment. They control processes based on a set of predetermined rules.

PLCs are implemented to enhance the efficiency, accuracy, and consistency of production processes. While the former substitutes human labor, PLCs reduce the need for it.

For example, in tablet production, PLCs are used in various segments, such as granulation and mixing, coating, packaging, and environmental monitoring. In granulation and mixing, PLCs ensure precision while they control spray rates, temperature, and drum rotation in the coating process.

What’s even better is that they may be programmed to perform a wider range of tasks, such as motor speed and direction control, alarm and warning systems activation, and fluid and gas flow control.

PLCs are known for their reliability and their capability to keep working continuously even for long periods, making them suitable in the toughest environments. You can customize or program them to perform various tasks or respond to various inputs as needed. Adaptability and flexibility, indeed.

Before concluding this talk, you must also learn about the benefits of these technologies.

Here are Canaan, we ensure that all of the pharmaceutical equipment we manufacture are products of detail-oriented research, development, and crafting.

Aside from our central and provincial engineering research centers, we also have a high-tech enterprise and research institutes that guarantee only the best for your industry.This is why we can provide the most ideal solutions for the pharmaceutical, healthcare, and food industries, among various others. Find out what’s in store for you now.

Before any drug reaches a patient, it starts in a lab. That’s where formulas are tested, batches are checked, and quality is either confirmed or questioned. To do that work right, labs depend on the right equipment—tools that don’t just get the job done, but do it with precision. If you’re responsible for running or […]

Blister packaging is everywhere in pharma—from tablets to capsules to sample packs. It protects the product, extends shelf life, and improves patient safety. But for manufacturers, it’s more than just packaging—it’s a system built around speed, precision, and compliance. If you’re in pharma manufacturing or packaging procurement, here’s what you need to know about blister […]

If you’re deciding how to deliver a pharmaceutical or supplement product, the format you choose—liquid gels or tablets—will shape more than just how it looks. It affects how the product is made, how fast it’s absorbed, what kind of equipment you’ll need, and how the end user experiences it. Some actives work better in a […]