Before any drug reaches a patient, it starts in a lab. That’s where formulas are tested, batches are checked, and quality is either confirmed or questioned. To do that work right, labs depend on the right equipment—tools that don’t just get the job done, but do it with precision. If you’re responsible for running or […]

From June 11 to 14, 2025, the ProPak Asia 2025 was grandly held at the Bangkok International Trade & Exhibition Centre (BITEC), Thailand. As one of the most influential processing and packaging exhibitions in Asia, the event attracted leading enterprises and professional visitors from the pharmaceutical, food, chemical, and packaging sectors around the world. With […]

Before any drug reaches a patient, it starts in a lab. That’s where formulas are tested, batches are checked, and quality is either confirmed or questioned. To do that work right, labs depend on the right equipment—tools that don’t just get the job done, but do it with precision. If you’re responsible for running or […]

Blister packaging is everywhere in pharma—from tablets to capsules to sample packs. It protects the product, extends shelf life, and improves patient safety. But for manufacturers, it’s more than just packaging—it’s a system built around speed, precision, and compliance. If you’re in pharma manufacturing or packaging procurement, here’s what you need to know about blister […]

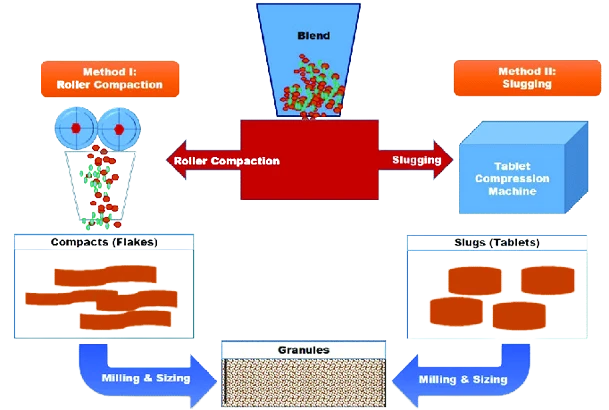

Dry granulation is a vital process across various industries, including pharmaceuticals, chemicals, and food production. It allows for the formation of granules without requiring a liquid binder, making it an essential method for moisture-sensitive materials. The two main techniques used for dry granulation are slugging granulation and roller compaction. While both methods achieve the same […]

Fluid bed granulation is a widely used process across various industries, especially in pharmaceuticals, chemicals, and food production. This process transforms fine powders into uniform granules, making materials easier to handle and more suitable for downstream processing, such as tableting or capsule filling. The importance of fluid bed granulation cannot be overstated—it ensures the uniform […]

How Does a Roller Compactor Granulation Work? In pharmaceutical manufacturing, granulation is a crucial step to convert fine powders into free-flowing granules, which are then used to produce solid dosage forms such as tablets or capsules. Granules are preferred because they have better flow properties and compressibility, which helps ensure uniformity in dosage and tablet […]

What Is Roller Compactor Pharmaceutical? In pharmaceutical manufacturing, the production of solid dosage forms—such as tablets and capsules—relies on precise processes to ensure consistent quality and efficacy. A crucial part of this process is granulation, where fine powders are transformed into granules that are easier to handle and compress into uniform tablets. Granulation improves the […]

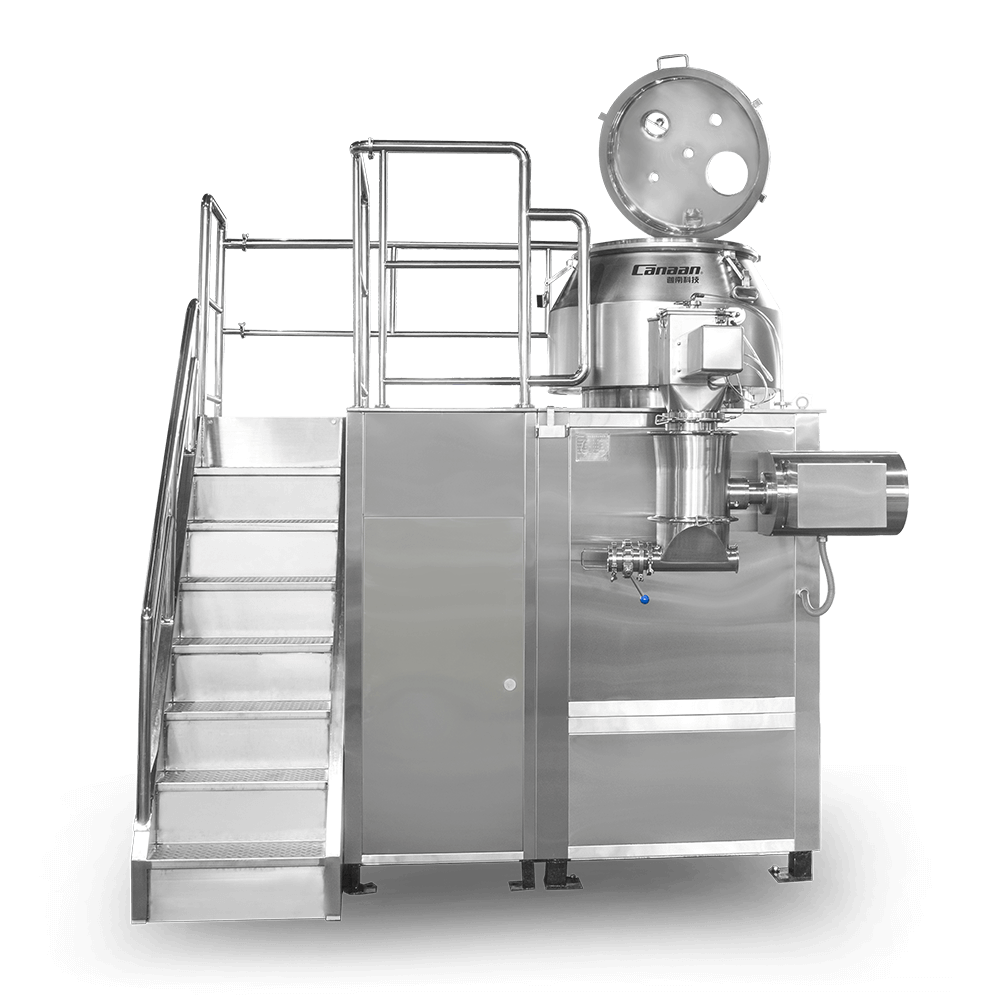

The Difference Between High Shear Granulation and Fluid Bed Granulation What is granulation? Granulation is a vital process in the pharmaceutical industry, primarily used to improve the properties of powders, such as flowability, compressibility, and uniformity. It converts fine powders into granules, which are easier to handle and process during the manufacturing of tablets, capsules, […]

What Is Fluid Bed Granulation? Imagine a method that turns a bunch of powder into perfect, easy-to-handle granules. That’s fluid bed granulation in a nutshell. What is fluid bed granulation? Fluid bed granulation is when fine powder is suspended in hot air, creating something almost like a fluid. Then, a binding agent is sprayed onto […]

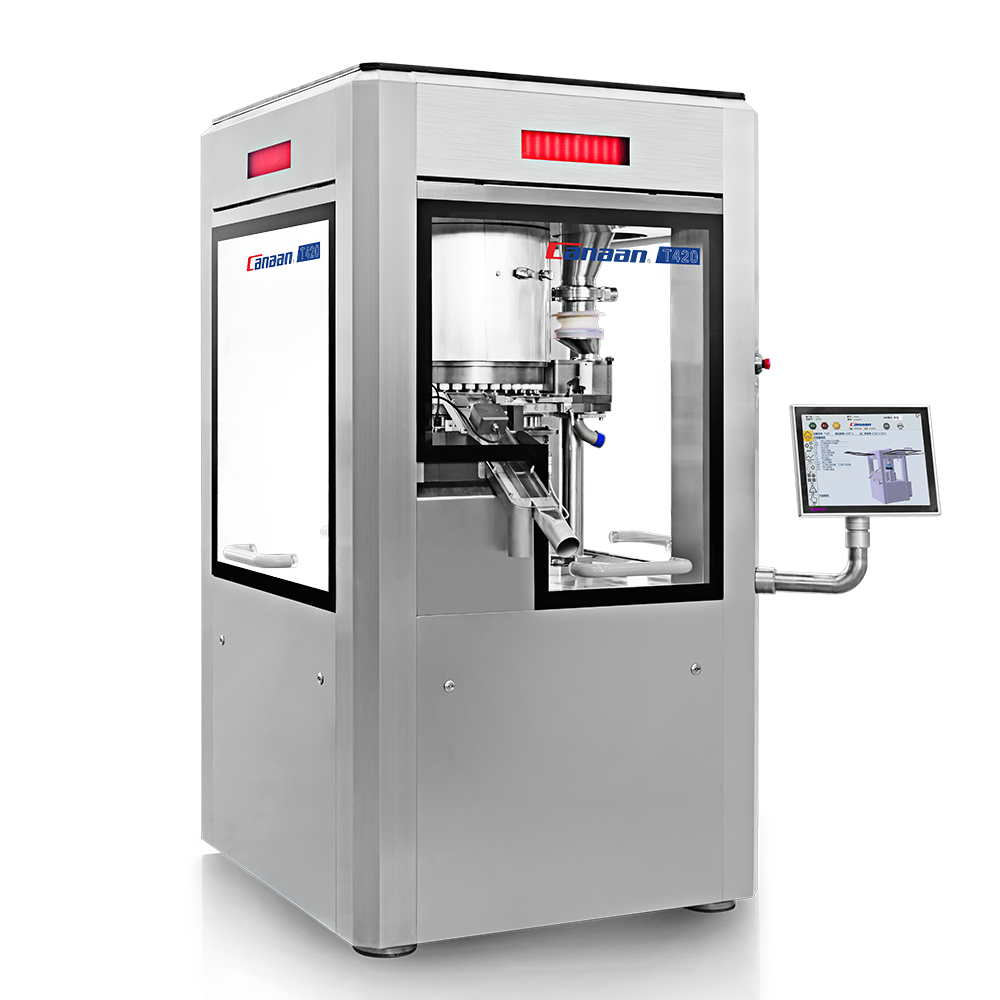

In the world of tablet manufacturing, choosing the right equipment is critical to ensuring efficiency, quality, and scalability. The two most common types of tablet press machines are the single-punch and rotary tablet presses. In this article, we’ll break down the key differences between single-punch and rotary tablet presses, helping you determine which is the […]

Sugar coating tablets is both an art and a science. It’s the process that gives many pills their smooth, shiny, and often colorful exterior. But why bother with this extra step? Sugar coating serves several purposes: it masks unpleasant tastes, protects the tablet from moisture, and makes pills easier to swallow. The Basics of Sugar […]

What Is the Tip Speed of a High Shear Mixer? High-shear mixers are essential in industries like pharmaceuticals, food, and cosmetics, where efficient mixing and granulation are critical. One of the key elements of these machines is tip speed, which significantly affects the mixing process. Discover the High Shear Mixer (with Mill) for efficient and […]

How Does a High-Shear Mixer Work? High-shear mixers play a big role in industries—pharmaceuticals, food production, cosmetics, etc—that require efficient blending and emulsifying of materials. They excel at creating homogenous mixtures quickly and with precision. In this guide, we’ll explore how high-shear mixers work, their key components, and why they’re indispensable in various industrial processes. […]

How Tablet Press Machines Work Tablet press machines are essential in the pharmaceutical, nutraceutical, and food industries, playing a crucial role in the production of tablets. From aspirin to vitamin supplements, these machines compress powders or granules into uniform, solid doses, which can then be packaged and distributed. Let’s explore how tablet press machines work, […]

Types of Tablet Press Machines Every pill tells a story of science, precision, and the amazing machines that bring them to life. Tablet press machines are the secret heroes behind the medicines we trust. They turn powders into the tablets we swallow without a second thought. But these machines aren’t one-size-fits-all. From small presses making […]