Preface: In 2024, automation and digital technologies will drive the rapid development of equipment manufacturing and high-tech manufacturing, and enterprises will transform towards high-end, intelligent.

A world-renowned multinational company has established its first “carbon neutral” production base in China, which will be built into a world-class “lighthouse factory” and gradually achieve the goals of “carbon neutrality” and “carbon peak”. The Fluid-bed Granulation Line customized and developed by Canaan Technology for it has successfully passed the FAT acceptance, marking that Canaan has taken a new step in its “customization”, “concentric diversification” and “internationalization” strategies.

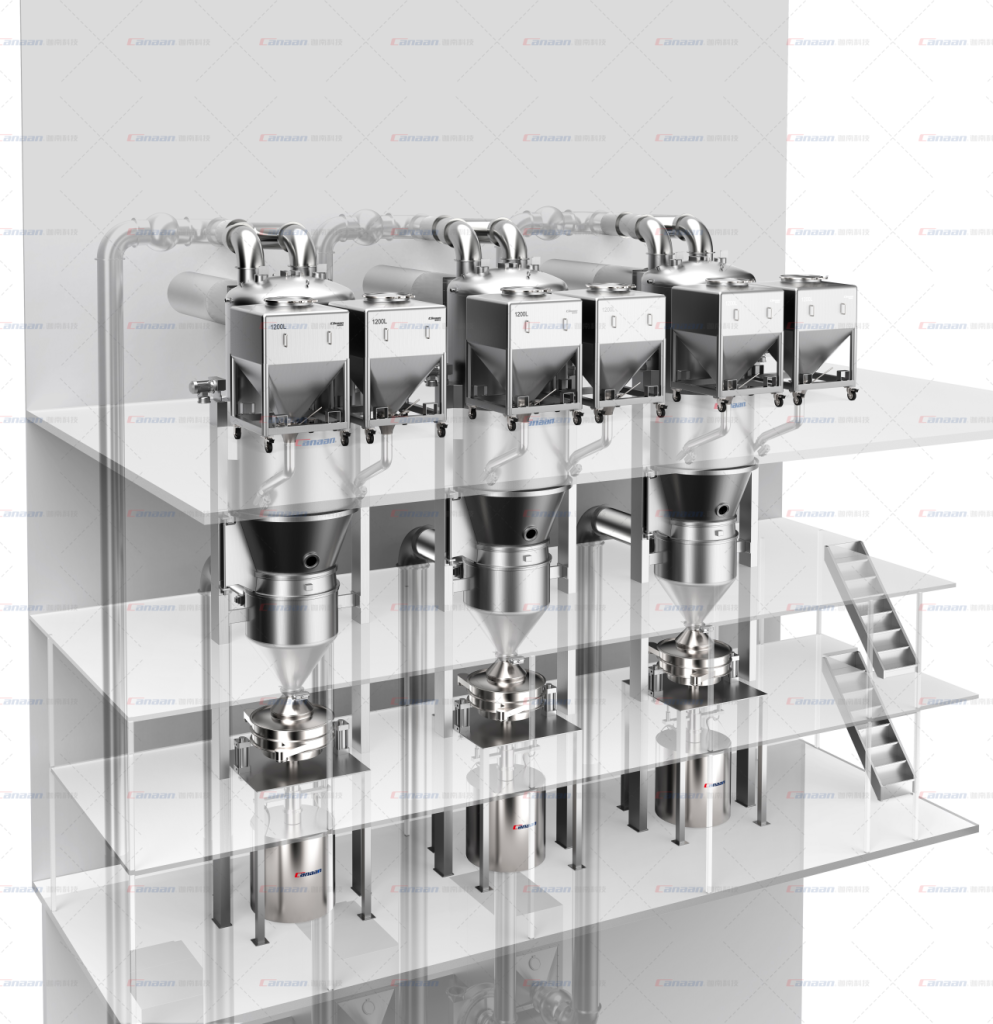

1. High degree of automation: covering the entire process of “feeding-granulation-drying-cooling-discharging-screening-ton bag packaging”, using an independent control system, and high degree of automation to meet the requirements of the “lighthouse factory”.

2. Large production capacity: The core equipment in the line – the maximum production capacity limit of the boiling granulator has been broken through, which can meet the maximum production capacity of 1000kg/pot.

3. High efficiency: The production time of each process step is extremely compressed, and a single unit achieves an ultra-high production capacity of 20 tons/day.

Gravity combined with vacuum feeding method, the feeding time can be controlled within 2 minutes.

The hot and cold air ducts of the air handling unit are completely separated, shortening the cooling time to within 5 minutes.

The material adopts the form of flap plus gravity discharge, and the discharge time can be controlled within 3 minutes.

4. Energy saving and consumption reduction: Heat recycling technology is used in the line, and the overall factory operation is finally realized to achieve carbon neutrality.

5. International high standards: Based on the application practice and technical accumulation of pharmaceutical equipment, the project can fully meet the requirements of international standard certifications such as EN, CE, EHEDG, IEC, etc. in terms of product design and manufacturing, explosion-proof safety, etc.

Canaan provides customized smart factory solutions for customers in the food, health care, new energy, medical beauty and other industries, based on its solid dosage intelligent solutions for the pharmaceutical industry. Canaan Technology always adheres to customer-centricity, continuous R&D and innovation, and takes automation, digitization, continuity, sealing, greening and efficiency as key points to help customers develop new quality productivity with higher technology level, better quality, higher efficiency and more sustainability.

Before any drug reaches a patient, it starts in a lab. That’s where formulas are tested, batches are checked, and quality is either confirmed or questioned. To do that work right, labs depend on the right equipment—tools that don’t just get the job done, but do it with precision. If you’re responsible for running or […]

Blister packaging is everywhere in pharma—from tablets to capsules to sample packs. It protects the product, extends shelf life, and improves patient safety. But for manufacturers, it’s more than just packaging—it’s a system built around speed, precision, and compliance. If you’re in pharma manufacturing or packaging procurement, here’s what you need to know about blister […]

If you’re deciding how to deliver a pharmaceutical or supplement product, the format you choose—liquid gels or tablets—will shape more than just how it looks. It affects how the product is made, how fast it’s absorbed, what kind of equipment you’ll need, and how the end user experiences it. Some actives work better in a […]